Mazda 6 Service Manual: Engine removal/installation

Warning

- Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep sparks and flames away from fuel.

- Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the Fuel Line Safety Procedure. (See Fuel Line Safety Procedure.)

1. Remove the battery. (See BATTERY REMOVAL/INSTALLATION.)

2. Remove the battery tray. (See BATTERY REMOVAL/INSTALLATION.)

3. Remove the radiator. (See RADIATOR REMOVAL/INSTALLATION.)

4. Drain the missions oil.

5. Remove the P/S oil pump with the oil hose still connected and position the P/S oil pump so that it is out of the way. (See POWER STEERING OIL PUMP REMOVAL/INSTALLATION)

6. Remove the A/C compressor with the pipes still connected. Position the A/C compressor so that it is out of the way. Use wire or rope to secure.

7. Remove the joint shaft from the front drive shaft. (See DRIVE SHAFT REMOVAL/INSTALLATION.)

8. Remove the air cleaner, intake air duct, accelerator cable and bracket, and vacuum hose. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

9. Remove the ATF filter and selector cable. (ATX) (See AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the vacuum hose and heater hose.

11. Remove the release cylinder and control cable. (MTX) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION.)

12. Remove the plastic fuel hose. (See Plastic Fuel Hose Removal Note.) (See Plastic Fuel Hose Installation Note.)

13. Disconnect the wiring harness from the engine side.

14. Remove the front pipe. (See EXHAUST SYSTEM REMOVAL/INSTALLATION.)

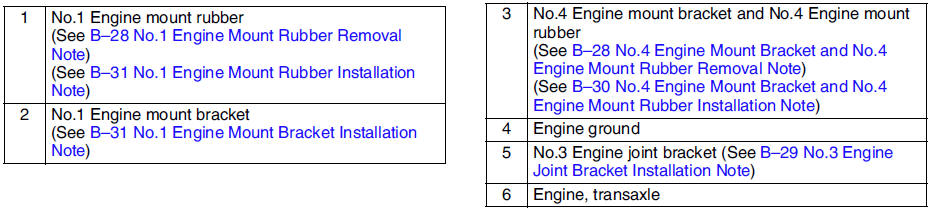

15. Remove in the order indicated in the table.

16. Install in the reverse order of removal.

17. Start the engine and:

- Inspect for the engine oil, engine coolant, transaxle oil and fuel leakage.

- Verify the ignition timing, idle speed and idle mixture. (See IGNITION TIMING INSPECTION.) (See IDLE MIXTURE INSPECTION.)

18. Perform a road test.

No.1 Engine Mount Rubber Removal Note

1. Suspend the engine using the SSTs

.

2. Remove the through bolt A on the No.1 engine mount bracket side.

3. Loosen the through bolt B on the chassis side until approximately three pitches are showing.

Note

- Do not remove the No.1 engine mount rubber from the vehicle.

No.4 Engine Mount Bracket and No.4 Engine Mount Rubber Removal Note

1. Secure the engine and the transaxle using an engine jack and attachment as shown.

2. Remove the SST

.

3. Secure the engine and the transaxle using a hoist.

4. No.4 engine mount bracket and engine mount rubber together in one piece.

No.3 Engine Joint Bracket Installation Note

1. Tighten the No.3 engine mount bracket stud bolt.

Tightening torque: 7.0-13 N·m {71.4-132.5 kgf·cm, 62.0-115.0 in·lbf}

2. Tighten the No.3 engine joint bracket bolt and nut in the order shown.

No.4 Engine Mount Bracket and No.4 Engine Mount Rubber Installation Note

1. Tighten the No.4 engine mount bracket and No.4 engine mount rubber bolt and nut in the order as shown.

2. Secure the engine and the transaxle using an engine jack and attachment as shown.

3. Remove the hoist and secure the engine and transaxle using SST

.

No.1 Engine Mount Bracket Installation Note

1. Tighten No.1 engine mount bracket bolt A.

Tightening torque: 93.1-116.6 N·m {9.50-11.88 kgf·m, 68.72-85.92 ft·lbf}

2. Tighten No.1 engine mount bracket bolt B.

Tightening torque: 93.1-116.6 N·m {9.50-11.88 kgf·m, 68.72-85.92 ft·lbf}

No.1 Engine Mount Rubber Installation Note

1. Tighten through bolt A on No.1 engine mount bracket.

Tightening torque: 85.3-116.6 N·m {8.7-11.88 kgf·m, 62.93-85.92 ft·lbf}

2. Tighten through bolt B on chassis side.

Tightening torque: 93.1-116.6 N·m {9.50-11.88 kgf·m, 68.72-85.92 ft·lbf}

Engine

Engine

...

Engine disassembly/assembly

Engine disassembly/assembly

1. Disconnect the engine and automatic transaxle. (ATX) (See AUTOMATIC

TRANSAXLE REMOVAL/INSTALLATION.)

2. Disconnect the engine and manual transaxle. (MTX) (See MANUAL TRANSAXLE

REMOVAL/INSTALLA ...

Other materials:

Mazda 6 Service Manual: Engine Coolant Temperature Gauge (Without Multi-information Display)

Displays the engine coolant temperature. The white gauge indicates that the engine

coolant temperature is low, and the red gauge indicates that the engine coolant

temperature is high and overheating.

CAUTION

If the engine coolant temperature gauge indicator flashes, there is a possibility

...

Mazda 6 Service Manual: Front Seat Belt Pretensioner and Load Limiting Systems

For optimum protection, the driver and front passenger seat belts are equipped

with pretensioner and load limiting systems. For both these systems to work properly

you must wear the seat belt properly.

Pretensioners:

When a collision is detected, the pretensioners deploy simultaneously with th ...