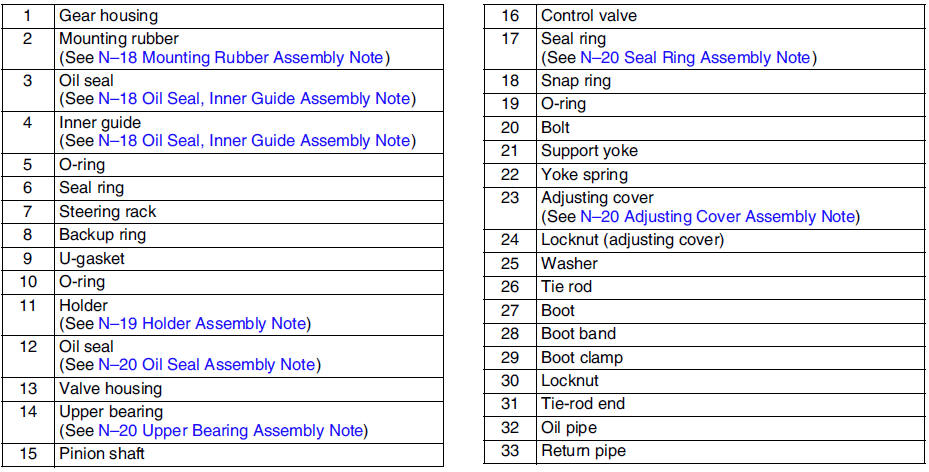

Mazda 6 Service Manual: Steering gear and linkage assembly

Caution

- Place copper plates, rag, or similar material in a vise, when secure the mounting bracket portion of the steering gear.

Assemble in the order indicated in the table.

Mounting Rubber Assembly Note

1. Apply soapy water to the rubber part of the mounting rubber.

2. Press the mounting rubber until the mounting rubber end comes out completely from the gear housing using the SSTs

and a press.

3. Reverse the gear housing, then press the mounting rubber until the mounting rubber end comes out completely from the other side. At this time, mounting rubber end and steel pipe are aligned.

Oil Seal, Inner Guide Assembly Note

1. Install a new O-ring and a new seal ring to the racks piston.

2. After installing the seal ring, seat it properly at the piston circumference.

3. Apply grease to a new oil seal and inner guide.

4. Install the oil seal to the SST

.

5. Using the SST

, place the oil seal and inner guide at the edge of the steering racks pinion, and remove the SST

.

6. After installing the steering rack to the gear housing, press the oil seal and inner guide using the SSTs

until the force required suddenly increases.

Holder Assembly Note

1. Apply grease to the U-gasket and O-ring.

2. Assemble the U-gasket, backup ring and O-ring into the holder.

3. Assemble the SST

to the steering rack.

4. Stake the holder to the cylinder using a punch.

Oil Seal Assembly Note

1. Apply grease to a new oil seal.

2. Press in the new oil seal using the SSTs

.

Upper Bearing Assembly Note

1. Apply grease to a new upper bearing.

2. Press in the upper bearing using the SST

.

Seal Ring Assembly Note

1. Install a new seal ring to the valve part of the pinion shaft using the SST

.

2. After installing it, seat it properly using the SST

.

3. Install the snap ring.

Adjusting Cover Assembly Note

1. Set the rack to the center position.

2. Tighten the adjusting cover to 4.9 N·m {50 kgf·cm, 36 in·lbf}

three times, then return it 25°

using the SST

.

3. Apply sealant to the threads of the locknut.

4. Attach the locknut.

5. Measure the pinion torque using the SST

and a pull scale.

Standard

Center of rack ±90°

0.8-1.2 N·m

{8.2-12.2 kgf·cm, 5.8-8.8 in·lbf} [Pull scale reading

8-12 N {0.9-1.2 kgf, 1.8-2.6 lbf}]Except center of rack ±90° Less than 1.6 N·m

{16.3 kgf·cm, 11.8 in·lbf} [Pull scale reading

Less than 16.7 N {1.7 kgf, 3.8 lbf}]

6. If not as specified, repeat steps 2 through 5.

7. Install the locknut using the SST

(49 B032 320).

Tightening torque 40-49 N·m {4.1-4.9 kgf·m, 30-36 ft·lbf}

Hermetic sealing inspection

1. Connect the SSTs

to the power cylinder section of the gear housing.

2. Apply 53.3 kPa {400 mmHg, 15.7 inHg}

vacuum with a vacuum pump and verify that it is held for at least 30 seconds.

3. If the vacuum is not held, replace the oil seal.

Steering gear and linkage inspection

Steering gear and linkage inspection

Rack Inspection

1. Inspect the rack for cracking, damage, and tooth wear. Replace it as

necessary.

2. Measure the runout of the rack.

Runout

Near point A: 0.15 mm {0.006 in} max.

Near po ...

Power steering oil pump removal/installation

Power steering oil pump removal/installation

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

...

Other materials:

Mazda 6 Service Manual: Windshield Defrosting and Defogging

Press the windshield defroster switch. In this position, the outside air position

is automatically selected, and the air conditioner automatically turns on. The air

conditioner will directly dehumidify the air to the front windshield and side windows.

Airflow amount will be increased.

WARNING

...

Mazda 6 Service Manual: Operating Tips for AAC

AAC stands for Advanced Audio Coding, which is standardized voice compression

established by the ISO*1 working group (MPEG). Audio data can be created and stored

at a higher compression ratio than MP3.

This unit plays files with the extensions (.aac/.m4a/.wav) as the AAC files.

*1 Internationa ...