Mazda 6 Service Manual: Control valve body installation

On-Vehicle Installation

Caution

- Be sure to align the parking rod and the manual valve.

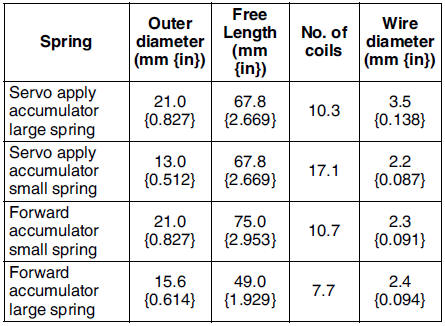

1. Install the accumulator springs and accumulators into the transaxle case.

2. Install the control valve body component.

Tightening torque 7.8-10.8 N·m

{80-110 kgf·cm, 70-95 in·lbf}Bolt length (measured from below the head) B: 40 mm {1.575 in}

No mark: 70 mm {2.756 in}

3. Install the oil strainer.

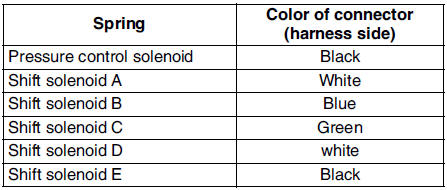

4. Match the harness colors, then connect the solenoid connector and TFT

sensor connector.

5. Install the ground.

Tightening torque 7.8-10.8 N·m {80-110 kgf·cm, 70-95 in·lbf}

6. Apply a light coat of silicon sealant to the contact surfaces of the oil pan and transaxle case.

7. Install the oil pan.

Tightening torque 6-8 N·m {62-81 kgf·cm, 53-70 in·lbf}

8. Install the crossmember. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION.)

9. Install the front tires and splash shield.

10. Install the under cover.

11. Connect the negative battery cable.

12. Add ATF and with the engine idling, inspect the ATF level. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT.)

13. Carry out the mechanical system test. (See MECHANICAL SYSTEM TEST.)

14. Carry out the road test. (See ROAD TEST.)

Control valve body removal

Control valve body removal

On-Vehicle Removal

Warning

Using compressed air can cause dirt and other particles to fly

out, causing injury to the eyes. Wear protective eyes whenever using

compressed air.

Caution

...

Oil cooler flushing

Oil cooler flushing

Note

The contaminated cooler line (oil pipes and hoses) and auxiliary

cooler must be flushed completely when ATX is overhauled or replaced.

1. Remove the two oil cooler line hoses and apply ...

Other materials:

Mazda 6 Service Manual: Variable tumble control solenoid valve inspection

1. Remove the variable tumble control solenoid valve. (See INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION.)

2. Inspect airflow between the ports under the following conditions.

If not as specified, replace the variable tumble control solenoid valve.

If as specified, carry out the Circuit Open/Short ...

Mazda 6 Service Manual: Side Air Bags

The side air bags are mounted in the outboard sides of the front seatbacks.

When the air bag crash sensors detect a side impact of greater than moderate

force, the system inflates the side air bag only on the side in which the vehicle

was hit. The side air bag inflates quickly to reduce injury ...